Main structure of TXP160 Screw Extruder

This machine is composed of a driving system, a feeding device, an extruding device, an electric control cabinet and so on.

Working Principle

This extruding machine can transfer mechanical energy to thermal energy by extrusion, friction and shearing function of non-equidistance screw extrusion system, and form a certain pressure and temperature in the extruding chamber, so material is sprayed out from the discharging die head to be expanded and formed.

Main Technical Parameters

| Items | Unit | Parameters |

|---|---|---|

| Treating capacity (output) | kg/h | 650~1350 |

| Rotating speed of main shaft | r/min | 630 |

| Rotating speed of feeder | r/min | 200~400 |

| Power of main motor | kw | 55 |

| Power of feeding motor | kw | 2.2 |

| Power consumption | kw·h/t | 35~58 |

| Noise | dB | 82 |

| Treatment (Processing) temperature (discharging end) | ℃ | 80~140 |

| Overall dimensions(LxWxH) | mm | 2150×2100×1280 |

| Weight of machine | kg | 1800 |

Installation and commissioning

- This machine should be installed on a flat foundation, it is better to install foundation screw, and a proper space around it should be remained in convenience for discharging, conveying and packing, and a certain space shall be remained for easy removal and maintenance.

- Incoming line of electric control cabinet shall be reasonably equipped based on motor power.

- Installation of connector of speed control gauge: align connector keyways with protuberant rib, insert the connector, and then tighten the fastening helicoids.

Screw Extruder Application

The machine is the single equipment integrated in raw material feeding, heating and extruding, which can be used for the below applications, as required by different extruding treatment, under 80—140℃ temperature, it can be adjusted by discharging die heads with different apertures, material can be dehydrated by 3—5% after being expanded.1. Application in oil mills

Crude oil manufactured by extruding and extracting technology is of light color and low acid value, it is easy to make advanced cooking oil in different levels; and bulk weight of material increases after being expanded, so that production capacity of extractor can be greatly improved and residual oil rate of dry cakes is lower than 1%. Raw material is naturally heated to about 110℃ after entering the extruder, and then sprayed out through die head (that is to say it is expanded and formed). During the extruding process, temperature of mechanical friction heat can inhibit activity of active teichomycin and can kill some fungi and microorganism, so that material will not deteriorate in a longer period.

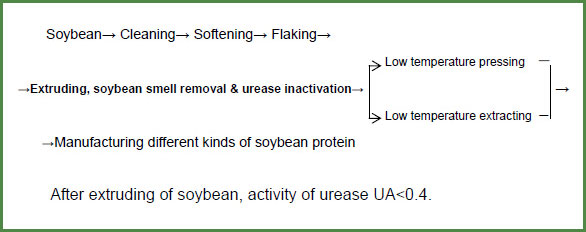

2. Application in soybean protein factories

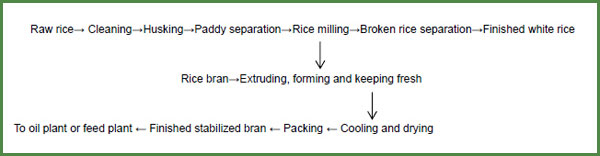

3. Technological flow for application in rice mills (for a rice mill over 200t/d)

4. Application in formula feed mills

Precautions Before Trial Run

- The incoming materials shall be cleaned without any foreign matters and impurities, especially the hard matters such as metal are forbidden to mix into the raw materials.

- Moisture content of raw material shall be kept between 12—14%, do not feed the oil-bearing materials with moisture content of less than 8%.

- The oil-bearing materials may not be put into the feeder some times more and some times less, and especially may not be fed intermittently, so as to ensure continuously stable and normal production of this machine.